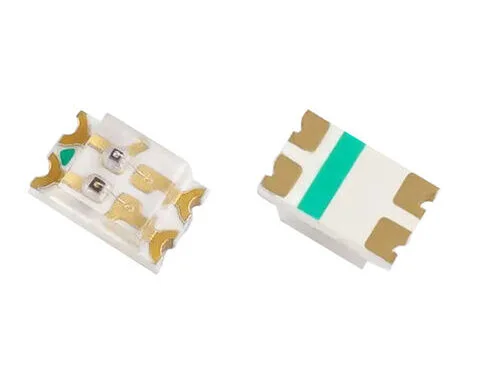

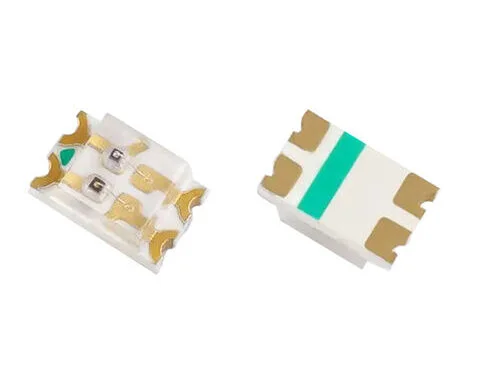

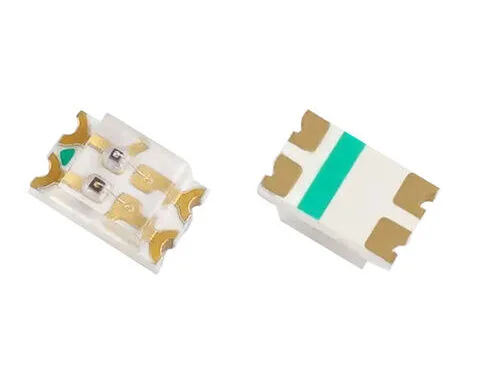

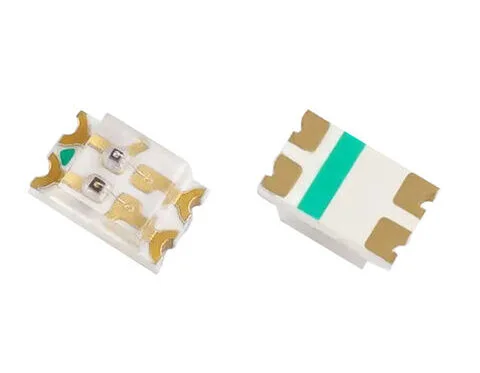

An Overview of Red LED SMD 1206 Package

The Red Surface Mount (SMD) LED in a 1206 package is a highly versatile and efficient light-emitting diode that has been designed to meet the needs of various lighting and indication applications. With its vibrant red light emission, this LED serves as an essential component in numerous electronic devices. The 1206 package size, which measures approximately 3.2mm x 1.6mm, is a standardized format in the world of surface-mount technology (SMT), ensuring compatibility with a wide range of PCB designs and manufacturing processes.

Specifications

The specifications of the Red SMD LED in a 1206 package are crucial for understanding its performance and suitability for different applications. Below are the key specifications:

| Parameter | Specification |

|---|---|

| Package Size | 1206 (3.2mm x 1.6mm) |

| Color | Red |

| Wavelength | Typically around 620-630 nm |

| Forward Voltage | 1.8V to 2.2V |

| Forward Current | 20mA (standard operating current) |

| Luminous Intensity | 50-200 mcd (millicandela) |

| Viewing Angle | 120° – 140° |

| Power Dissipation | 75mW |

| Operating Temperature Range | -40°C to +85°C |

| Storage Temperature Range | -40°C to +100°C |

| Reflow Soldering Temperature | Peak at 260°C for 10 seconds |

Features

- Compact Size: The small 1206 package allows for high-density PCB layouts, making it suitable for compact electronic devices.

- High Brightness: Emitting a vibrant red light, this LED provides clear visibility, which is essential for status indicators and displays.

- Low Power Consumption: With a forward voltage typically between 1.8V and 2.2V, this LED is energy-efficient, which is crucial for battery-operated devices.

- Wide Viewing Angle: The 120° to 140° viewing angle ensures that the LED is visible from various perspectives, enhancing its effectiveness in display applications.

- Durability: Designed to withstand a range of environmental conditions, including extreme temperatures and humidity, this LED offers reliable performance over time.

- Reflow Soldering Compatible: Suitable for automated PCB assembly processes, including reflow soldering, making it ideal for mass production.

- RoHS Compliant: Free from hazardous substances, aligning with global environmental regulations and standards.

Applications

- Status Indicators: Commonly used in electronic devices to indicate operational states, power status, and error signals.

- Displays: Integral in creating alphanumeric and graphic displays, particularly in digital clocks, calculators, and instrument panels.

- Backlighting: Used for backlighting in LCDs and keypads to enhance visibility in low-light conditions.

- Decorative Lighting: Suitable for aesthetic and decorative purposes in consumer electronics, toys, and gadgets.

- Automotive Electronics: Used in dashboard indicators, interior lighting, and other automotive electronic systems.

- Medical Devices: Employed in various medical equipment for indication and illumination purposes.

- Consumer Electronics: Widely used in remote controls, gaming consoles, and household appliances.

Developments

- Efficiency Improvements: Ongoing research focuses on enhancing luminous efficiency, reducing power consumption while maintaining or increasing brightness.

- Material Innovations: Development of new semiconductor materials and phosphor blends to achieve better color rendering and higher performance.

- Integration with Smart Technologies: Incorporating smart features like dimming, color tuning, and integration with IoT devices for more interactive and energy-efficient lighting solutions.

- Miniaturization: Continuous efforts to reduce the size of LEDs while maintaining performance, enabling even more compact and lightweight electronic designs.

- Thermal Management: Advanced thermal management techniques to enhance the longevity and reliability of LEDs in high-power applications.

- Environmental Sustainability: Focus on developing LEDs with lower environmental impact, using eco-friendly materials and manufacturing processes.

Instructions for Use

- PCB Design:

- Ensure the PCB layout accommodates the 1206 package dimensions.

- Design appropriate solder pads to facilitate reliable soldering connections.

- Consider thermal management strategies to dissipate heat efficiently.

- Soldering:

- Use reflow soldering techniques for best results. Preheat the PCB to avoid thermal shock.

- Peak reflow temperature should reach around 260°C for no more than 10 seconds.

- Avoid excessive soldering time and temperature to prevent damage.

- Electrical Characteristics:

- Apply the correct forward voltage (1.8V to 2.2V) to avoid overdriving the LED.

- Limit the forward current to the recommended 20mA to ensure longevity and prevent thermal damage.

- Implement current-limiting resistors or constant current drivers as necessary.

- Handling and Storage:

- Handle LEDs with care to avoid mechanical stress and electrostatic discharge (ESD) damage.

- Store LEDs in a dry, anti-static environment. Avoid exposure to moisture which can affect performance during soldering.

- Testing and Inspection:

- Test the LEDs after soldering to ensure proper functionality and brightness.

- Inspect for any soldering defects, such as cold joints or bridging, that can affect performance.

Conclusion

The Red Surface Mount (SMD) LED in a 1206 package is a crucial component in modern electronic design, offering a combination of compact size, high brightness, and energy efficiency. Its robust features and wide range of applications, from status indicators to decorative lighting, make it indispensable in the electronics industry. With ongoing advancements in LED technology, the capabilities and performance of these components continue to improve, paving the way for even more innovative and efficient electronic solutions.

For more related products: Click here

For more services: Click here

Reviews

There are no reviews yet.