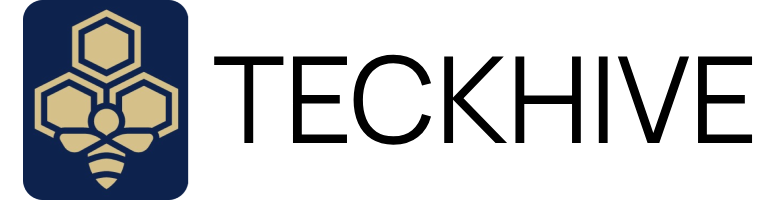

BK2000 Eddy Current Heating Lead Free Soldering Station: An Overview

The BK2000 Eddy Current Heating Lead-Free Soldering Station is a cutting-edge soldering tool designed for professional use. Utilizing advanced eddy current heating technology, this station delivers rapid and precise heating, ensuring efficient soldering without the use of lead. Its digital display allows for easy temperature monitoring and adjustment, while its ergonomic design and intuitive controls make it user-friendly. Whether for intricate electronic repairs or large-scale soldering projects, the BK2000 offers reliability, precision, and safety, making it an indispensable tool for soldering professionals.

Specifications:

| Specifications | Details |

|---|---|

| Intelligent lead-free soldering station | BK2000 |

| Operating Voltage | AC230V/50Hz |

| Temperature Range | 200°C∼480°C |

| Maximum instantaneous power | 120W |

| Temperature Stability (no load) | ±2°C |

| Resistance of soldering iron tip to ground | <2Ω |

| Potential of soldering iron tip to ground | <2mV |

| Dimensions | L150xW130xH105mm |

| Password lock function | Yes |

Features

- Eddy Current Heating: This technology uses a high-frequency alternating current to induce eddy currents within the soldering iron tip. This results in rapid heating and recovery times, allowing you to reach your desired temperature quickly and maintain it consistently.

- Digital Temperature Control: The BK2000 features an easy-to-use digital interface with an LCD display for setting and monitoring the soldering iron tip temperature. Buttons allow for precise temperature adjustments in small increments.

- Password Lockout: This feature prevents unauthorized tampering with temperature settings, ensuring consistent and reliable soldering results.

- Auto-Sleep and Auto-Power Off: The station automatically enters sleep mode after 20 minutes of inactivity, reducing tip temperature and prolonging tip life. After 60 minutes of no use, it automatically powers off completely, saving energy and preventing accidental burns.

- ESD Design: The BK2000 incorporates electrostatic discharge (ESD) protection to safeguard sensitive electronic components from damage during soldering.

Applications

The BK2000 is well-suited for various lead-free soldering applications, including:

- Electronics Repair: This station is ideal for repairing and servicing a wide range of electronic devices, such as smartphones, laptops, motherboards, and other circuit boards.

- Component-Level Soldering: The precise temperature control and fast recovery times make the BK2000 suitable for soldering delicate electronic components like SMD (surface-mount devices) and fine-pitch connectors.

- Prototyping and Assembly: The BK2000 can be used for prototyping new electronic circuits and assembling electronic devices in research and development environments.

- Educational Use: Due to its user-friendly interface and safety features, the BK2000 can be a valuable tool for electronics training programs in vocational schools and universities.

Development in Soldering Technology

The BK2000 represents an advancement in soldering technology by incorporating eddy current heating. Compared to traditional heating methods that rely on resistive elements, eddy current heating offers several advantages:

- Faster Heating and Recovery: Eddy currents heat the soldering iron tip more efficiently, allowing you to reach your desired temperature quicker and maintain it consistently during soldering tasks.

- Improved Temperature Control: The precise control over the heating process offered by eddy currents translates to more accurate and stable soldering temperatures, reducing the risk of damaging heat-sensitive components.

- Longer Tip Life: Faster heating and recovery times minimize the time the tip spends at high temperatures, extending its lifespan and reducing the need for frequent replacements.

Instructions for Use (General Guidelines)

1. Preparation:

- Ensure you have a clean and well-ventilated workspace.

- Place the soldering station on a stable and heat-resistant surface.

- Attach the desired soldering tip to the soldering iron handle and tighten the screw securely.

- Inspect the tip for any damage or debris and clean it if necessary.

2. Power Up and Set Temperature:

- Plug the soldering station into a compatible power outlet and turn it on.

- Use the control buttons on the base unit to set the desired soldering temperature according to the type of solder and components you’ll be working with.

3. Soldering Process:

- Allow the soldering iron tip to reach the set temperature.

- Apply a small amount of solder to the tip to tin it, creating a thin, even coating. This improves heat transfer and solder flow.

- Wipe off any excess solder with a damp soldering sponge.

- Prepare the components you want to solder by cleaning the soldering points with appropriate cleaning solutions to remove any dirt or oxidation.

- Position the components securely using tweezers or other holding tools if necessary.

- Place the tip of the soldering iron onto the soldering point, ensuring good contact with both components.

- Apply a small amount of solder to the joint, allowing it to flow between the components by capillary action. Do not force the solder or hold the iron tip in place for extended periods.

- Once the solder has formed a good connection, remove the soldering iron tip and allow the joint to cool undisturbed.

4. Cleaning and Maintenance:

- After soldering, clean the soldering iron tip regularly with a damp soldering sponge while the tip is still hot. This removes solder residue and prevents tip oxidation.

- Periodically, use a tip cleaner specifically designed for lead-free soldering to remove any stubborn buildup on the tip.

- When the tip becomes worn or damaged, replace it with a new tip compatible with the BK2000 (200 Series Tips).

- Allow the soldering station to cool completely before storing it. Wipe down the exterior with a damp cloth for cleaning.

5. Safety Precautions:

- Always wear appropriate safety gear while soldering, including safety glasses to protect your eyes from flying solder spatter and a fume extractor to remove harmful fumes released during the soldering process.

- Be mindful of the hot soldering iron tip and avoid touching it to prevent burns.

- Use a soldering iron stand when the iron is not in use to prevent accidents and burns.

- Never leave the soldering station unattended while powered on.

- Ensure the soldering station is properly grounded to prevent electrical shock hazards.

For more related products: Click here

For more services: Click here

Reviews

There are no reviews yet.